Commercial services

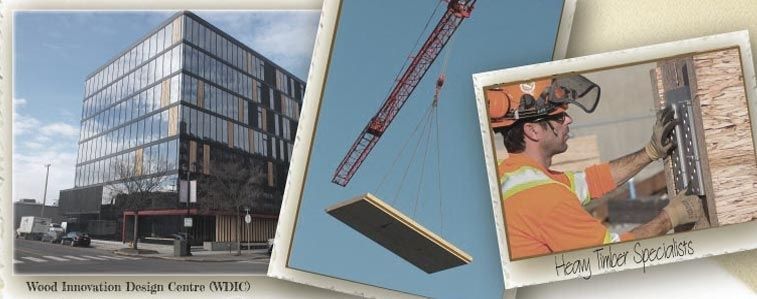

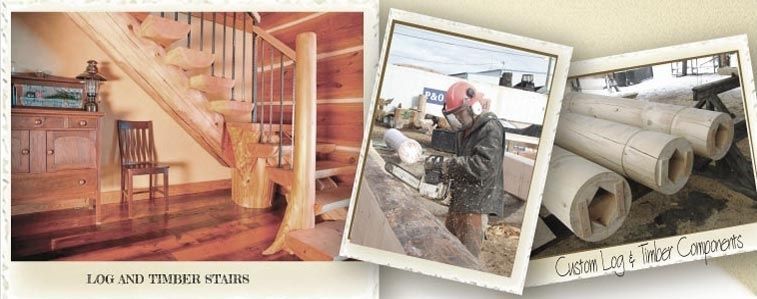

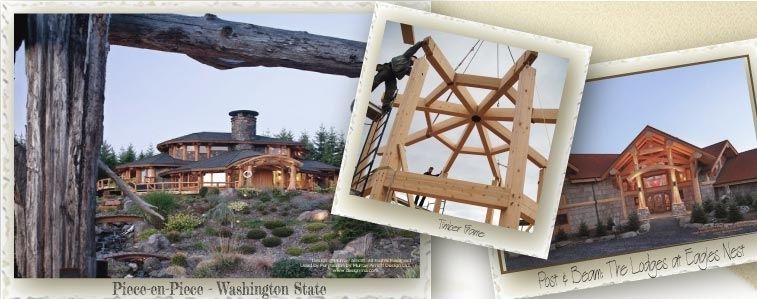

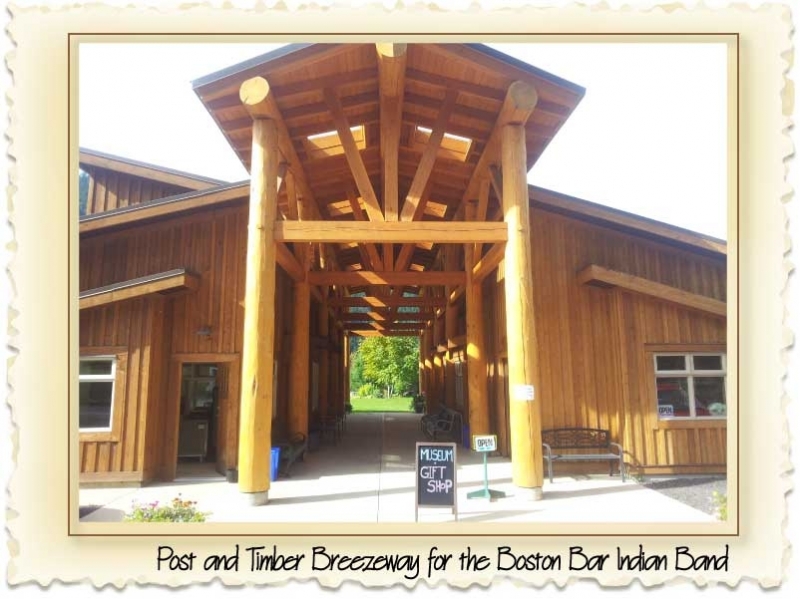

- Nicola LogWorks has been producing log and timber components such as trusses, parts and pieces; posts, timbers and miscellaneous mass engineered wood joinery to commercial contractors for many years. More recently our mastery of timber joinery, crane training and rigging skills have coincided with the introduction of CLT (Cross Laminated Timbers) to the North American market, positioning John Boys and Company in an arena for which their specialized expertise is highly applicable and well-suited and earning us the title of "Heavy Timber Specialists".

- You can view an interesting video produced by the Economist about the use of CLT in urban high rise structures - here:

Wooden skyscrapers could be the future for cities | The Economist

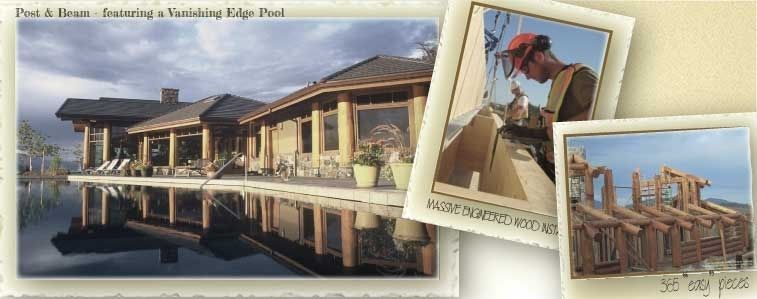

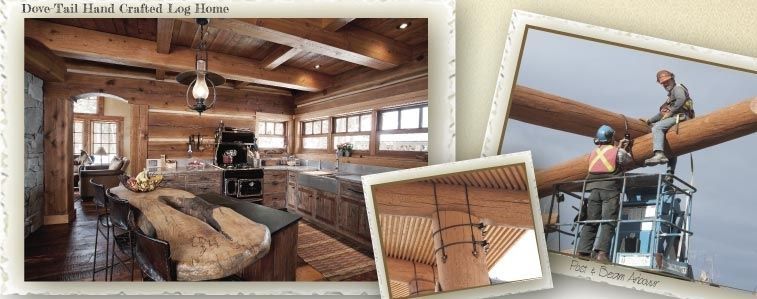

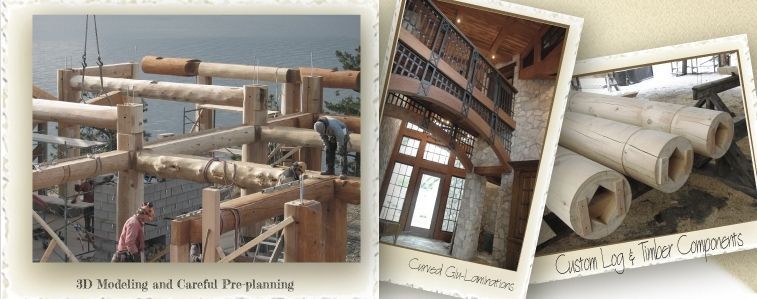

- Our commercial services include cutting and producing log and timber components and joinery using natural logs and/or dimensional timbers (FOB),as well as coordination and installation of our in-house log and timber products. We specialize in CLT and Engineered Wood Installations, consulting, pre-planning and crane strategies and consulting.

Engineered Wood Products - installations & related services

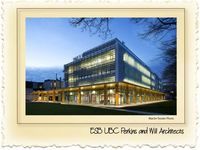

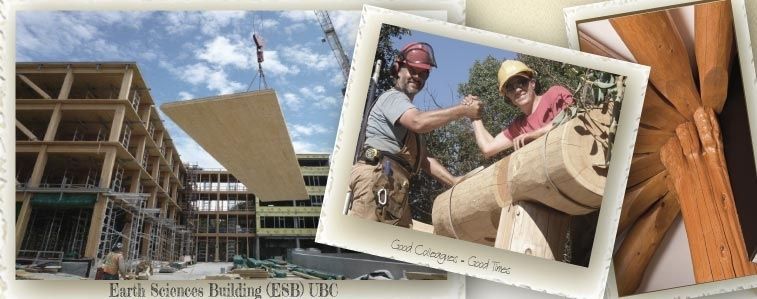

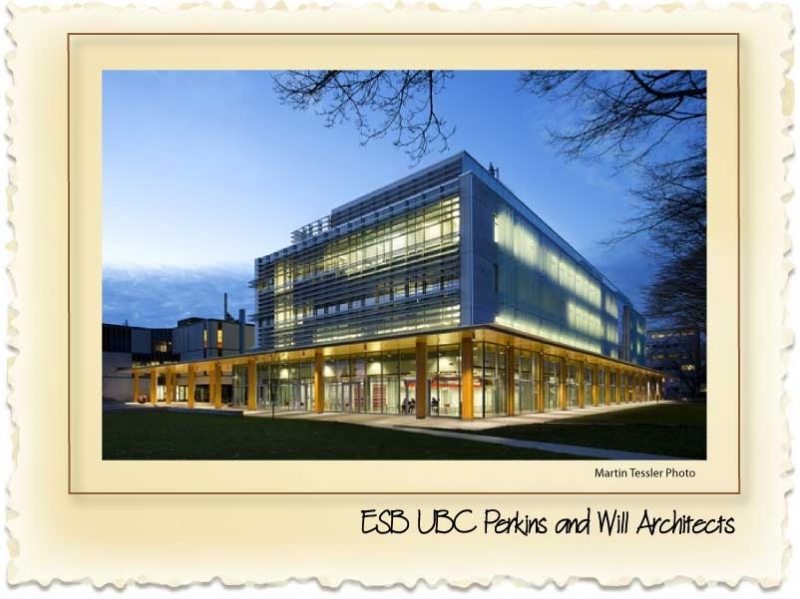

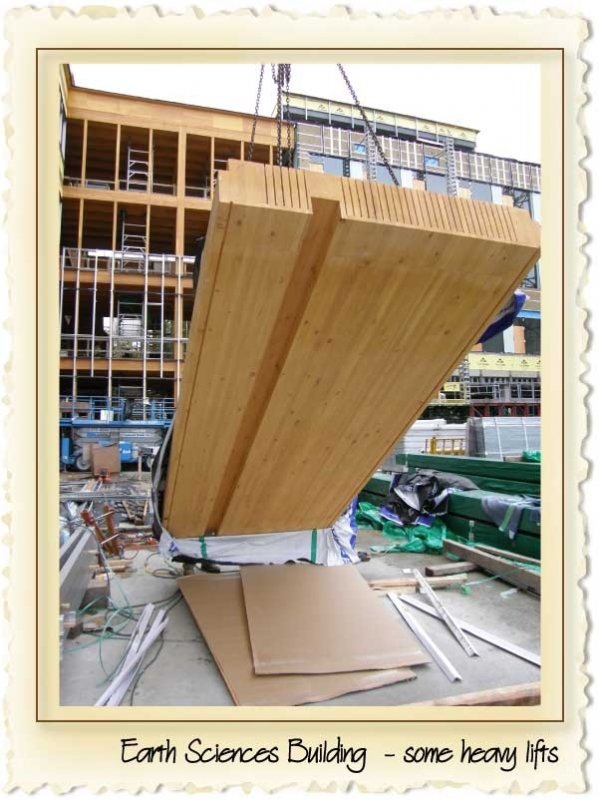

Our entry in to the arena of commercial construction began in a serious way when John Boys was invited to consult on lifting and assembly strategies at the Earth Sciences Building (ESB) which was being erected at the University of BC in the spring of 2011. Three days of advising evolved into a summer's worth of work for the crew of Nicola LogWorks and a handful of our talented colleagues who joined us to rescue the install of the heavy timber components of the building.(Gluulam and CLT).It was the first public structure in North America to use Cross-Laminated Timber (CLT) panels produced in Canada (by Structurelam Products - Penticton) and the contractor's crew were unfamiliar with handling, rigging and lifting mass-timber, not to mention the particulars of wood to wood joinery.

Our entry in to the arena of commercial construction began in a serious way when John Boys was invited to consult on lifting and assembly strategies at the Earth Sciences Building (ESB) which was being erected at the University of BC in the spring of 2011. Three days of advising evolved into a summer's worth of work for the crew of Nicola LogWorks and a handful of our talented colleagues who joined us to rescue the install of the heavy timber components of the building.(Gluulam and CLT).It was the first public structure in North America to use Cross-Laminated Timber (CLT) panels produced in Canada (by Structurelam Products - Penticton) and the contractor's crew were unfamiliar with handling, rigging and lifting mass-timber, not to mention the particulars of wood to wood joinery.

As it turns out - log and timber builders have a well honed skill-set in these areas. At Nicola LogWorks we also have a long tradtition of being hyper-cognizant of the materials and methods used by the other trades into whose work we tie into, or that of those who follow our installation. A solid foundation in sophisticated 3-D modelling was an additional asset that we brought to the process.

While the roots of our passion remain in production, we have found that the coordinating, sequencing and pre-planning that are a part of heavy timber installations are challenges that agree with our pursuit of procedure very well also. Process, work methods and problem solving are what we are about regardless of the size or scope of the work that we undertake.- To our credit are:

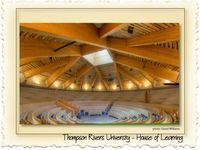

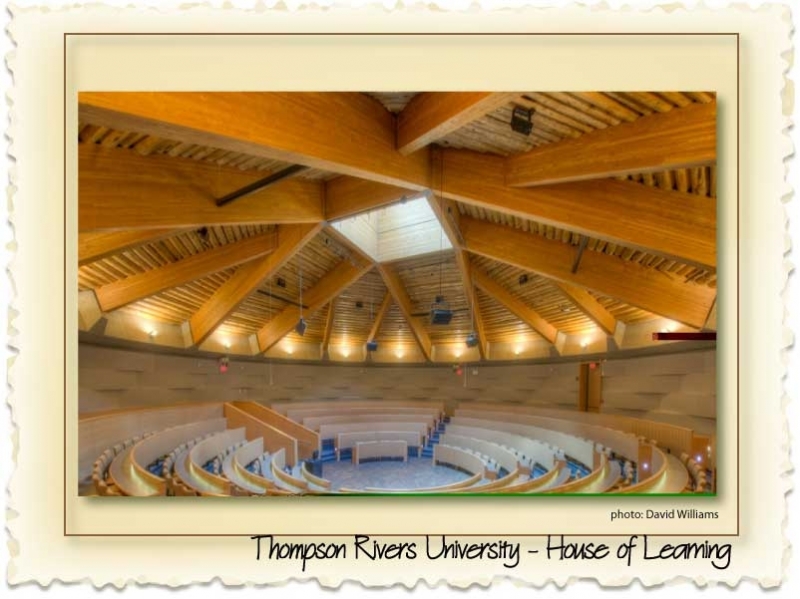

2009: TRU (Thompson Rivers University - House of Learning: Survey/Solution development, Glulam install and fabrication and installation of log roof panels. Architect David Nairne and Associates, Engineer:Fast & Epp, Contractor: Vanbots

2012: Fort McMurray Airport Expansion: Installation of CLT and Glulam. Survey and solution development. Architect OMB (Beth Denny),Engineer EQ Consulting (Eric Karsch and Bernard Gafner).

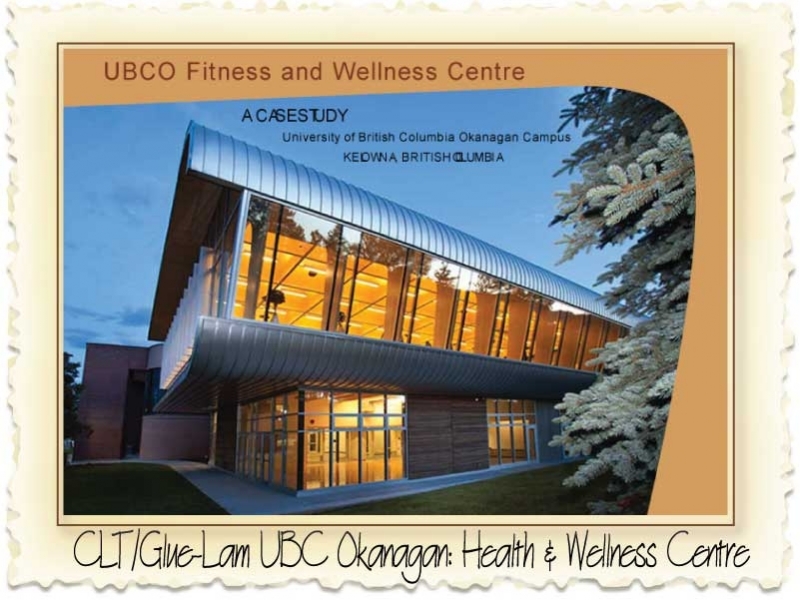

2012: UBC O (University of BC Okanagan) Health and Wellness Centre:Installation of CLT panels

2013: UBC Student Union Building:Installation of CLT and Glue-lam Installation. Project Manager - Bird Construction VancouverUBC Okanagan Health and Fitnesss Centre. Owner UBC. Contractor :Kindred Construction

UBC SUB (Student Union Building). Installation of Glu-lam and Cross Laminated Timber. Owner: UBC Properties. Contractor : Bird Construction.

Christina Lake Infrastructure Building. CLT and Glu-lam. Owner Cenovus Energy. Contractor Maple Reinders.

2014: Wood Innovation Design Centre (WDIC) for the University of Northern BC. Contractor PCL

2015: The Grizzli Winery Kelowna BC

2016: The ATCO Headquarters in Calgary. Owner ATCO, Contractor CANA